Below you will find pages that utilize the taxonomy term “Rust Diaries”

Rust Diaries: Post scriptum

Since Tomek is currently laying down the carpet in the Impreza and will soon start installing the seats, I thought it would be a good time to write a little summary.

Is it worth it?

Yes, definitely yes. Time takes its toll, and although this particular example was in objectively good condition (see sills, shock absorber mounts, and fenders), I don’t know how it would have looked in a few years time. Now, I can sleep a bit more peacefully. Besides, there’s a lot of fun in all this work — we laughed like beavers chomping on aspen twigs. There’s also satisfaction — maybe not exactly “build not bought”, but something along those lines.

Rust Diaries: The interior

During the summer holidays, we stripped the interior from the dashboard to the trunk; now it’s time to finish the job. Although I’m already in Poznań, Tomek is still working on it. The condition is actually very good, no holes or deep rust pitting.

The method is exactly the same as for the undercarriage: stripping, sanding, and using the chemicals. The only difference is that instead of Cobra, Tomek is applying 02C paint as the final layer.

Rust Diaries: All things are important, but some are more important

Of the important ones, with a big smile on my face, I’m happy to report that the Impreza will soon have all its clips in perfect condition. I spent a fair bit of time under the car and noted all the missing, broken, and suspiciously hanging by a thread clips, and as always, my local Subaru specialists stepped up to the task. I’m also really happy about the sponges for the fuel tank roll over valve and fuel pump access flap, they were in pretty bad shape, and are notoriously hard to come by.

Rust Diaries: The chemicals

Since I’m not a painter and don’t really have anyone to consult on the matter, the only thing left for me to do was to go through a huge number of threads where car enthusiasts battle with the oxidation of iron and its alloys. The real results are delayed, so my choices will be verified in a few years — who knows, maybe I’ll have to eat my words. Here are my conclusions, in the order of application (for the visually inclined, photos follow).

Rust Diaries, Day 24: The engine

If you know your Subarus, you should know that with those flat fours, it’s a tale of “when”, not “if”. With a slight summer delay, I’m reporting the pickup of the Impreza from Nowy Sącz. It started innocently enough, but ended the way it always does. The list consists of 59 items, and the bill… a bit more than 59 PLN. The cylinder hone to the first oversize, and everything associated with it, was done properly, without cutting corners on costs.

Rust Diaries, Day 23: On its own wheels

We’re wrapping up this project. Floor pan splash shield and the rear diffuser. Exhaust.

Front and rear bumpers with lights. Wheels. And after a month, the car is back on its very own BBS forged alloys.

Rust Diaries, Day 22: The end is in sight...

…or maybe: The end is near!

The front and rear brakes are installed, and while we were at it, the handbrake shoes were replaced.

The front wheel arches, mudguards and rocker panel covers are installed. All the missing clips have been replaced.

Rust Diaries, Day 21: Fuel filler neck

The fuel filler neck is assembled. It might sound like a silly little part, and it is, but there are plenty of components to put together, not to mention all the pipes going in and out of the vapor canister.

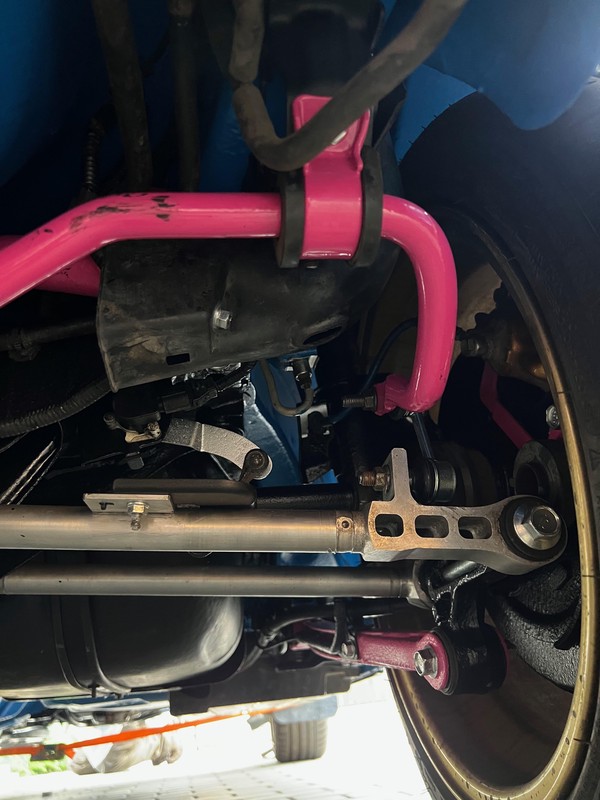

The rear sway bar and a pair of new links have been installed because the old ones had an encounter with an angle grinder.

Rust Diaries, Day 20: Rear axle II

It’s starting to look really nice. The rear suspension is finally reunited with the car.

And the most important thing, we figured it out — well, actually Tomek’s Dad figured out how to save the snapped bolts in the chassis beam. He welded two small plates to each of the two nuts, which we inserted through the service holes into the correct position. Then, we secured them with screws so that the plates were positioned against the lower plane of the beam. We then drilled a hole through both the beam and the plate, so that a rivet could be inserted through. It turned out perfectly — the rivet held the nut in the correct position so that we could start the thread, and thanks to the plates, we could properly tighten the bolt (without having a wrench on it), as the plates wedged inside the beam. It was done without cutting or welding anything.

Rust Diaries, Day 19: Rear axle

Well, now we’ll see. Anyone can take something apart.

Today, we assembled the complete rear axle, including the differential and its housing, subframe, and trailing arms.

Rust Diaries, Day 18: The last day of painting

Cobra in the engine bay.

Final touches on the gearbox housing (a keen eye might notice that Tomek decided to celebrate the end of painting with a rather cute sweater):

Rust Diaries, Day 17: Black and pink

Following up on the work done on Day 15, we finished with all the large and small parts; they received a final coat of Cobra. Black for the most and pink (STI pink, if you like) for the smaller bits. This was inspire by those iconic trailing links ST2027055000, that’s RAL 4010, if you’re wondering.

A quick look at the home paint shop.

Rust Diaries, Day 16: Truck Bedliner

The work’s picking up pace. Today, we opened the first can of Cobra – a textured truck bedliner coating based on two-component polyurethane resins, which is going to make the final layer on the underside of the car. I was a bit apprehensive about this moment and wasn’t sure how RAL 5017 would look on the car. But I think it turned out quite well. Yes, it’s brighter than 02C - World Rally Blue, but once everything that the roads have to offer covers it, it will look class. Cobra on the rear wheel arches and up to the gearbox line:

Rust Diaries, Day 15: Subframes II

Following up on the work done on Day 12, we continued with all the large parts that didn’t make it to the powder coating: Dinitrol and the primer.

I spent some time and effort on the lateral link set — steel wool works wonders on those aluminum pieces.

Rust Diaries, Day 14: Halfway point (?)

The theoretical halfway point (I gave myself a month to finish this), but we’ll see how it turns out in the end. The engine bay won’t be stripped; we wouldn’t have had enough time, plus some of the work required could have been too much for us to handle — like rerouting the fuel and brake lines. After all, our technical consultant deserves our respect and we would not want to over work him. As a result, brown packing paper in hand, it’s time to start packing things up. We’ll finish stripping at the chassis beams level.

Rust Diaries, Day 13: From big to samll

The next logical step was to tidy up all the remaining small parts, and that’s exactly what we did. Quite a few of them went through zinc plating.

Rust Diaries, Day 12: Subframes

During the break from the sheet metal on the underside, we tackled the bigger parts: subframe, trailing arms, differential and driveshaft mounts, sway bar — basically everything we could get our hands on. The only difference was that all those parts went straight into sandblasting. As the car had only 56,000 km on it, the bushings were in very good shape, so we decided against powder coating the parts with the bushings, as it would ruin them in the process–for those it was the usual treatment Dinitrol and Interplus. There’s something to be said about those OEM parts — sure, you could replace them with the likes of Powerflex, but that didn’t feel right. Everything else was powder coated, though.

Rust Diaries, Days of abrasion

The first grinding sessions quickly turned into worn-out discs, bald brushes, and soot-covered faces. The days blended into a blurred continuity, punctuated by Dinitrol and Interplus 256. Our best friends became the angle grinder and the power drill. For the most stubborn areas, we resorted to sand blasting, but that was definitely the minority.

I like this picture quite a lot; it shows the stages nicely: in the middle, bare metal; to the right, covered with Dinitrol RC 900 – rust converted and primer; and finally, on the far right (ahem), still untouched.

Rust Diaries, Days 4 and 5: Brushes

Some conceptual work, preparation for cleaning, and testing of various wire brushes and polyamide abrasive discs were done.

The car’s body was wrapped to protect the paintwork and then moved under the shelter.

We also managed to disassemble the rear axle.

Rust Diaries, Day 3: Rear suspension and fuel tank

It’s warm, so the car is melting quickly. Today, we dismantled the entire rear suspension: struts, springs, brakes, axles with the differential, the fuel tank, and the rear crossmember. The work is going surprisingly well; Tomek’s dad is well skilled.

On the downside, we snapped two bolts — one from the diff mounting and one from the rear suspension trailing arm. There’s a nearby access hole, but we don’t have much hope for success.

Rust Diaries, Day 2: Turntable mounts and gearbox

Whit the chassis frame entry points in sight it was now time to attach the mounts. As described in a previous post the front required angle brackets welded in, which attach to the frame with two bolts and slide in to the turntable nicely:

The back fits just as snugly, utilizing the bolt holes originally present on the frame:

Rust Diaries, Day 1: The starting point

Goal for today: main chassis frame. We don’t have a garage lift (at least not yet), so the plan is to do all the work using a paint-shop-style turntable. This will give us good up-and-down movement, and when we need to strip the underside, we should be able to tilt the car sideways easily. The inserts for the chassis frame will be made from 50x50mm thick-walled profiles (which fit perfectly into the internal profile of the turntable mount). At the rear, there will be 3 bolts on each side, directly into the frame rails. At the front, an angle iron will be welded to the profile, with 2 bolts on each side, going into the beam mounting holes.

Rust Diaries, Day 0: Nowy Sącz

Alarm set for 5 a.m., quick coffee, and off we go. Of course, via Jasło and Gorlice, not the A4 — never miss a chance to take a few more corners. By 8:04, we’re at the workshop: Tomek in a tow truck from a friend, and me in the Impreza. Rendezvous back at 12. By 12:58, this is the view:

It will be a good few weeks before that EJ257 will be reunited with the rest of the car.

About those two guys who decided to...

The idea for the project is simple: on one hand, it should be as close to the original as possible, but on the other , it should last for years. My boys are already thinking about who they will pass the car on to, even though they’re still at an age far from being able to drive. I’m lucky that the community around the brand is active and eager to share their experiences. A lot of inspiration and know-how comes from the online forums.